Calculating Voltage Drop for Safety and Performance

InfoPower blogs are created to assist you in designing, building, and maintaining products for worldwide markets by providing you with information on topics relevant to power system components.

Mon Aug 03 2020

You have a cord connected to a power source on one end and a machine on the other. The good news is that you have power and the machine is working. The bad news is that you have just started using the machine without calculating for voltage drop as the cord length is 65 feet—for long cord assemblies (50 feet or more) it’s important to calculate voltage drop due to potential safety risks.

So you calculate for voltage drop and discover you are slightly over the 5% drop limit required by NEC Rule 210.19, and also the CSA requirement stating that voltage drop should be no more than 5% from service entrance to point of use. UL 817 requires cord sets to be derated after 50 feet and 100 feet to minimize issues with overheating due to voltage drop. Some specialized cord assemblies also have length restrictions in place. Some countries, such as the UK (BS 7671), also have requirements in place. Therefore, it is wise to check with safety agencies if planning to send equipment with long cords to another country. By exceeding the 50-foot cord assembly, you might put an employee’s safety at risk, or create a potential fire hazard. Not to mention damaging the machine you’re currently using.

“The loss of power to equipment reduces the voltage and overall power available to the equipment,” said Dan Ford, Technical Support Specialist at Interpower. “If too much voltage is lost, the equipment may not function correctly or may not work at all. For some equipment, such as devices that employ compressors, large motors, or pumps, even a small loss of voltage may cause a problem.”

Think of voltage as the pressure through a water hose and the hose itself as resistance, i.e., its thickness and diameter which help impede the flow of electrons. Insulation inside the cord has the same effect—the more insulation inside the cord (plastic, cardboard, etc.,) the slower the electrons will flow. This impedance of Alternating Current (AC) has a two-dimensional quantity creating both resistance and reactance, the latter due to an electric field resulting from changing current—the “pushed” current must be greater than the amount of resistance.

Voltage drops may cause lights to flicker or appliances to overheat—the load works harder with less voltage pushing it through. As a general rule, voltage drop should never exceed 5%. This is done by selecting the right size of wire, and by taking care in the use of extension cords and similar components. Heat buildup in a wire or cable can damage insulation.

“The type of damage can range from a degradation (breakdown) of the insulation material to a softening of the material, which could result in tearing if the cable or wire is bent or moved,” Ford said, “or outright melting of the insulation and exposure of the conductor wire beneath. Regardless, this reduces the life of the wire or cable and can lead to other safety issues. Excessive heat build-up can also degrade the conductor material and result in an increase in resistance, which compounds the issue, causing more voltage drop and more heat.”

The material of the wire and the size of the wire are also important. Copper is a better conductor than aluminum and will have less voltage drop than aluminum for a given length and wire size. The higher the voltage, the more electrons that can be sent flowing through the wire. And larger wire sizes (those with a greater diameter) will have less voltage drop than smaller wire sizes of the same length. In American wire gauge, every 6-gauge increase in wire size gives a doubling of the wire diameter, and every 3-gauge increase in wire size doubles the wire cross sectional area.

Safety Issues

Two common safety issues include shock and fire. “If the insulation is damaged to the point it tears or melts away exposing conductor wires, a user might touch the exposed area and receive a shock,” Ford said. “As voltage drop increases, so does the heat buildup. Too much heat can cause the weakening of the material to the point where arcing between conductors could occur, further increasing the risk of fire, especially around combustible material such as carpeting.”

Interpower’s Policy in Calculating Voltage Drop

“Interpower’s policy is to calculate voltage drop for requested long cord assemblies and notify the customer of any potential issues if the voltage drop could be over 5%. In these cases, we will let the customer know our findings which are calculated at a full rated load and ask for details regarding their application’s voltage and current usage,” Ford said. “We will then recalculate. If there is still an issue, we can assist the customer in trying to decrease the voltage drop by suggesting alternate, larger cable sizes where possible. Increasing cable size or decreasing length are the only two options for decreasing voltage drop. In cases where the voltage drop is too severe—in excess of 8%—Interpower reserves the right to refuse manufacture of such items due to safety concerns.”

Using Manual Calculation or the Voltage Drop Calculator

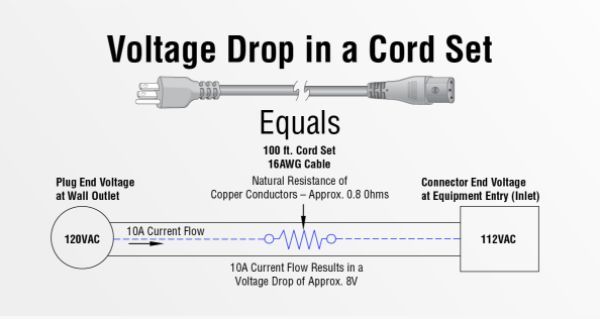

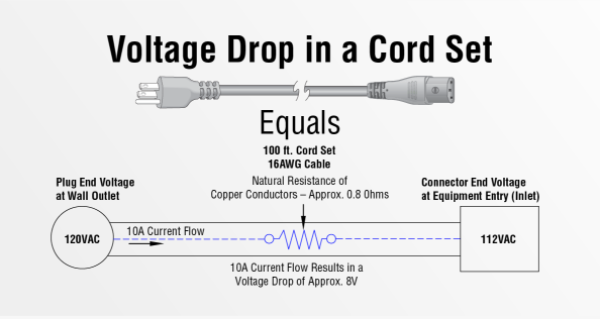

In order to manually calculate voltage drop, one must first obtain the expected direct current resistance from the applicable standard, or measure the resistance through the length of cable. Standards supply this information in ohms/km and sometimes ohms/1000ft. If taking a value from the standards, the value given must be converted/reduced to ohms/ft. For North American cable, Tables 5 and 6 in UL 62 should be used to obtain the value. For international cable types, such as H05VV-F, “IEC 60228 Table 1” should be used. These numbers will not give exact voltage drop numbers, but will be close enough to identify potential issues.

Once the ohms/ft. of a cable size is known, one must multiply this value by the length of the assembly in feet. This gives the total expected resistance for that assembly. Then it’s a matter of applying Ohm’s Law: multiply the resistance value of the assembly by the steady state current to get the voltage drop (if the current is going to fluctuate a lot based on parts of the application shutting on and off, use the highest value). One can then use this value with the mains voltage value to determine the remaining voltage and percentage loss.

Voltage Drop Calculator

An easier way is to go online and search for a “voltage drop calculator.” Supply the details requested and it will automatically calculate the voltage drop, percentage loss, and remaining voltage. Be warned, however, that most of these are set up for North American AWG cable. For international sizes use the closest corresponding AWG size. This can be obtained by looking at UL 62 or contacting a cable manufacturer for assistance. An example of a good voltage drop calculator is the Voltage Drop Calculator on calculator.net. It provides a cable chart on the same page that can be helpful to the user as well.