Barcodes: The Labels That Keep on Tracking

Barcodes have come a long way since their first patent was approved in 1952. From the workhorse of the 1-D barcode to 2-D and QR codes, it is not an overstatement to say the barcode has revolutionized how companies, institutions and agencies manage inventories. And a whole lot more.

Thu Jan 21 2021

Barcodes have come a long way since their first patent was approved in 1952. From the workhorse of the 1-D barcode to 2-D and QR codes, it is not an overstatement to say the barcode has revolutionized how companies, institutions and agencies manage inventories. And a whole lot more.

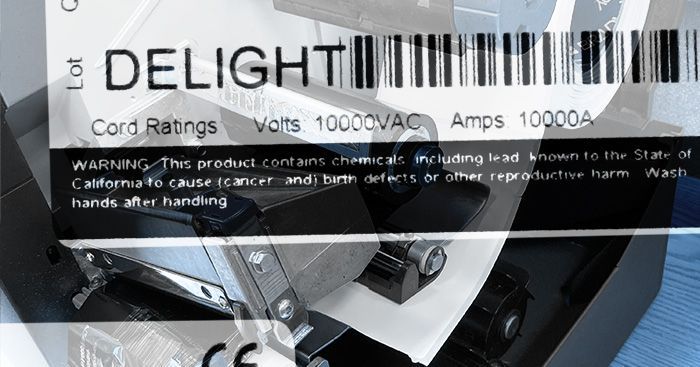

Example of 1-D Barcode

Example of 1-D BarcodeDue to the rapid influx of smart phone technology in the new millennium and its ever-increasing applications, 2-D and QR codes and micro QR codes can direct multi-industry consumers to company Websites, products, and other information via the flash of a scan. The 2-D codes are comprised of boxes or similar shapes (think Tetris) with solid lines at the borders while QR codes contain solid boxes at the corners. These small blocky, boxy codes can contain hundreds of characters for the scanner to read whereas 1-D barcodes contain far less.

Example of 2-D Barcode (QR Code)

Example of 2-D Barcode (QR Code)

Barcode Basics

A rudimentary definition of a barcode, especially the 1-D variety, is a machine-readable code in the form of numbers or alphanumeric designations and a pattern of parallel lines of varying widths, printed on and identifying a product which may include location, category, price, and other identifiers. Typically barcodes are scanned and automatically entered into a software system. That software data connects to global distribution systems allowing companies to manage inventories and logistics.

Interpower’s Value-added Barcode Service

At Interpower, the barcoding of cords and cord sets are a value-added service. When customers place orders for electrical and electronic products such as cords and cord sets, they have options. Interpower production staff take pride in ensuring customers receive the customized barcodes they ordered. Many companies use barcoding to manage their inventories.

An inventory tracking system is comprised of the aforementioned software and a barcode scanner, smart phone, or other scanning device. Inventory items (products such as cord sets or components or raw materials) often have barcode labels, so when you scan the barcode you add or remove them from stock, keeping tabs on your inventory—it can automatically be tracked in your software, saving you time from typing in a Stock-Keeping Unit (SKU).

Customer barcode criteria often include one or more of the following: Global Trade (GT) ID numbers, lot codes, and 2-D or QR codes. The first 14 numbers on the barcode is the company’s GT code. The set of numbers after the GT ID represent lot codes and production dates as well as many other identifier numbers as a company may prefer.

If there are smaller barcodes above the GT ID, those codes may be lot codes and customer part codes which are also scannable. Labels with multiple barcodes may contain a company logo or multiple logos. The logos are likely used both as a product identifier and for marketing purposes. The label may contain several foreign languages accompanying the codes depending on place of manufacture or destination.

Barcode Printing Machine at Interpower

Barcode Printing Machine at Interpower

Barcode Labels

The quality and accuracy (how the code is arranged on the label) is yet another quality control at Interpower—it must be accurate, centered and in dark enough font. Interpower uses both wax and paper labels depending on their destination and use. If one vertical bar is too close to the edge, it likely will not read properly. Centering the label also demonstrates quality workmanship—the customized barcode label must delight the customer.

Medical

The FDA requires that all institutions dispensing medicines place barcodes on those medicines. What the agency does not require is what the label materials should be or their positioning, i.e., their “quality.” If scanning an extremely small vial label that is not centered, wrinkled, or too curved, the label may not scan. This led to the use of smaller 2-D barcodes that are easier to scan. These barcodes have life-saving consequences, as getting the right patient the right dose of the right medicine is vital. The 2-D barcodes on medicine containers is just a small sample of barcoding used by the medical industry.