Brand new broken motor mounts on Instrument

RE: Centrifuge Report Post

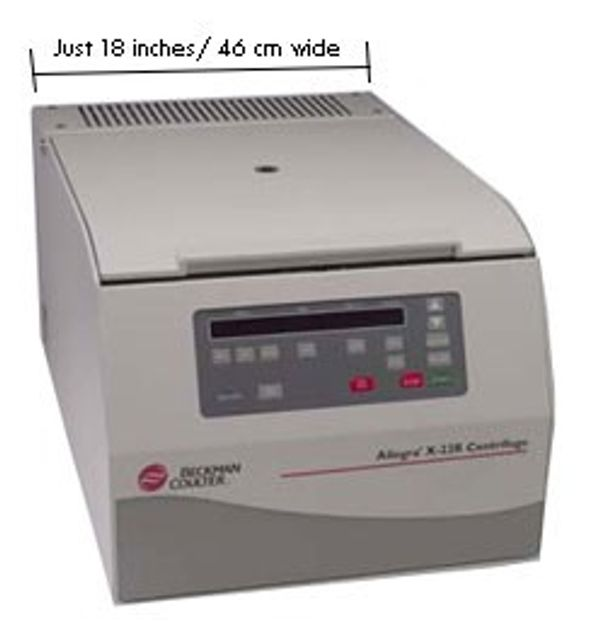

What is the name of the manufacturer and model of the equipment you are working on?

Find me on Facebook, LinkedIn, YouTube or Twitter

Report Post

Hello,

Sorry, Gmail has been blocking your site for some reason. I answered your question yesterday but it never made it.

The Instrument is a Beckman X-22r built in 2000.

Report Post

I would start by disconnecting X2 from the main pcb. If you measure the brake resistors through the plug, you should measure approximately 165 ohms. Secondly, if the main pcb has the transparent K1 and K2 relays, inspect them for arcing. If either one of these or both are identified as questionable, I recommend replacing the main pcb (our part number is 10129). Thirdly, as a precaution, I would check with the lab personnel and inquire about running balanced loads and whether loads are exceeding allowable parameters for instrument. Additionally, you mentioned having to replace the imbalance sensor. I have to ask, but was the imbalance recalibrated / checked following replacement of the sensor? And lastly, it is always a good idea to inspect the rotor, rotor trunnions and buckets for wear and proper lubrication.

Please give us a call at 1-800-457-7576 if you have any additional questions or concerns.

Report Post

Thanks for your advice! I had a feeling after looking over the schematics that there is a possibility of the K1 and K2 relays arcing or sticking could cause the problem I was experiencing. The instrument is still in the lab but I will start these new test procedures once I can get my hands on it. I plan to recheck the error table again to see if anything new was reported. Thanks again.

Report Post